RM series sealed box type multipurpose furnace

Introduction to RM series sealed box type multipurpose furnace:

RM series multi-purpose furnace is a high-grade controlled atmosphere sealed box type multi-purpose furnace designed and manufactured in full accordance with European standards. All components are manufactured in accordance with high standards, and all key components are made of German or other foreign brands. The equipment is a two chamber structure, which is heated in the rear chamber in a nitrogen methanol atmosphere. It can be used for carburizing, carbonitriding or heating in a protective atmosphere. The front chamber is equipped with a lift and a quenching oil tank. The workpiece is heated and quenched in a sealed state, which is safe and reliable. It is mainly used for carburizing, quenching, normalizing, tempering and other heat treatment processes of gears, pins, bearings, hydraulic parts and other products.

Features of RM box type multipurpose furnace:

1. The heating chamber adopts silicon carbide muffle structure, so that the furnace temperature in the heating chamber is uniform, the atmosphere circulation is more reasonable, and the product quality is better.

2. The low voltage electric radiant tube is driven by a transformer, so that the radiant tube has a long service life and is safe and reliable.

3. The chain pushing structure in the front chamber makes the workpiece safe and reliable in the process of feeding and discharging and quenching. All drives are driven by SEW reducer, which is safe and reliable, and is convenient for emergency treatment in the case of power failure and gas stop.

4. The nitrogen methanol atmosphere is adopted, and the control is accurate. It is not easy to produce carbon black. The carburized workpiece is of good quality, safe and reliable.

5. The touch type human-computer interface in full Chinese can realize three operation modes: automatic, manual and adjustment, and realize dynamic monitoring of equipment, process preparation, process tracking, temperature carbon potential recording and alarm recording.

6. All key components are imported brands, ensuring the quality of the equipment.

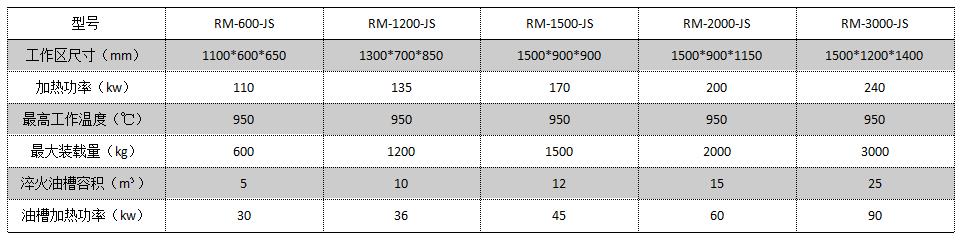

Equipment parameter table:

Quality of workpiece heat treatment:

After carburizing, the workpiece has beautiful appearance, excellent carburized layer structure, ideal carburized hardness gradient and carbon profile.

The workpiece has good strength and wear resistance, and has high overall fatigue, bending, tensile strength and impact toughness, which can meet the metallographic structure evaluation standards of different industries. The production line of controllable atmosphere multipurpose furnace can meet various process requirements and processes of users in different industries.