Large tonnage tempering production line

Summary

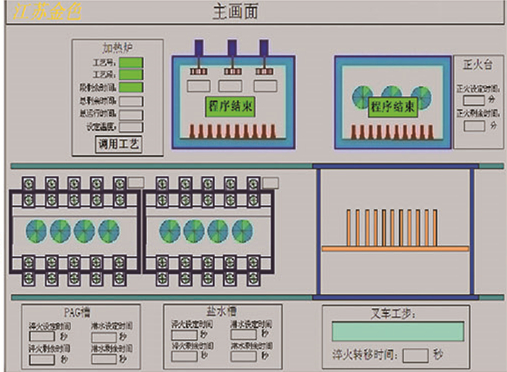

The production line is composed of box type heating furnace, quenching tank, quick cooling table, three-axis linkage forklift and full-automatic control system of the production line. Centralized control is adopted for the whole production line. All large tonnage workpieces can be quenched, tempered and normalized without pallet. Several processes can be compiled on the touch interface, and all heat data (including heat number, material number, operator, temperature, process time, etc.), alarms, process curves, etc. The operator can read and understand the current and historical data of the equipment at any time.

Box type heating furnace is composed of furnace body, furnace lining, furnace door, furnace door lifting device, furnace door closing and pressing device, electric heating system, forced convection system of air flow in furnace, air supply control system, heating control system, safety shield and maintenance platform. The equipment will automatically complete the whole process of workpiece feeding, heating, insulation and discharging according to the prepared process program.

Equipment control characteristics

1. It includes the layout plan of the whole production line and single equipment divided by different colors, and displays the working status, work steps, basic position status, temperature set values, and temperature process values of each single equipment.

2. Process parameters: including part name, process number, temperature and time of various process parameters.

3. Fault alarm: including display of current fault and display of historical fault.

4. Data record: The data at the cursor ruler can be displayed by moving the cursor ruler left and right, and can be zoomed in and out.

Multi fork X-Y-Z three-axis linkage forklift

The three-dimensional fork X-Y-Z three-axis linkage manipulator is controlled by PLC to realize the fully automatic transverse movement of the cart, the longitudinal movement of the fork trolley and the lifting movement of the fork, complete the workpiece transfer of the heating furnace, quenching tank, rapid cooling platform and material preparation platform, the workpiece quenching process of the heating furnace and the feeding and unloading of all equipment.

PAG quench tank

The quenching tank is composed of tank body, circulating cooling system, underwater forced mixing system, liquid level detection device, temperature measurement device and control system. In the tank (around and at the bottom), there are several groups of underwater forced mixing devices. The underwater agitator on the tank wall can adjust the mixing speed according to the flow direction of the liquid, and the fluid velocity and flow can be adjusted through the frequency control of the agitator. The circulating cooling system is used for cooling the quenching liquid to ensure that the quenching liquid can quench the workpiece within the controlled temperature range.

Normalizing table

The normalizing table is used for normalizing the workpiece after heating, or for temporary storage of the workpiece to be heated. The normalizing table is composed of material table, support frame, air collecting hood, fan, etc.